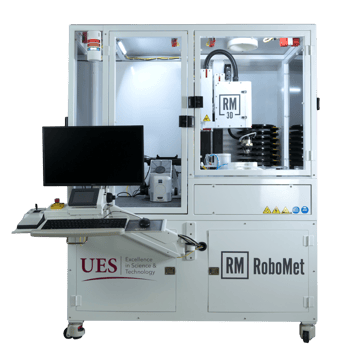

Robo-Met Builds Momentum in 2021

August 18, 2021

UES' Robo-Met team has made some new strides in 2021, building on the momentum gained in 2020. Learn more about our strides in technology transfer and industrial manufacturing below.

Read also: 2020 Research Using Robo-Met's Materials Analysis

Materials Characterization Research

Materials Characterization Research

The remote operability of Robo-Met enabled researchers to keep up their work momentum, and focus on analysis. Read up on materials characterization research featuring Robo-Met's automated material analysis in this article: "2021 Research Using Robo-Met's Materials Analysis." Looking for more Robo-Met-related research? We've got you covered with Robo-Met Publications in 2019, 2018, and 2017.

NASA SBIR Phase II Award

We were thrilled to be recognized for providing ground truth data in the NASA SBIR Award last fall. For this project, our Robo-Met team collaborated with Penn State University's Applied Research Laboratory (ARL). We developed probability of detection (POD) curves for nondestructive evaluation (NDE) techniques such as CT in the additive manufacturing (AM) processes for component quality control and post-build inspection. We are glad to share that we've been informed by the NASA SBIR office of selection for a Phase II Award! We've also been notified of a win with the DMEA for adapting Robo-Met for electronics delayering. Stay tuned for news on this exciting new application.

Robo-Met Upgrades

We announced our new Robo-Met upgrades including ZEN imaging and Windows 10 functionality in 2020. Check out the webinar here, and see why many of our customers upgraded right away. We're excited to continue to innovate and improve to help you get the insights you need to solve your materials challenges.

New Robo-Met Units

We've welcomed new customers into the Robo-Met user group this year! We're excited to announce we have completed installations of Robo-Met systems at NASA Langley and NASA Marshall. Our customers love Robo-Met's low-touch and automated nature, which allows them to limit contact in their characterization labs. Later this year, we plan to complete installations at the Fraunhofer IWS Dresden, and the University of PIttsburgh! To keep up with us, opt-in for Robo-Met updates here, so we can share product updates, event information, and more.

You can learn more about Robo-Met and how it can help you solve your materials challenges here. Have particular material challenges you’d like to discuss with our experts? Contact us here.

Questions? Contact us here. Connect with us on Facebook, Twitter, LinkedIn, and Instagram.